We have developed a custom-built 3D-printed clamp that attaches to a tube (such as an IV line) and continuously monitors the liquid flowing through the tube. It is able to identify in realtime the liquid, and displays that information. Changes to the type or concentration of the liquid are constantly monitored, and alerts may be issued if unsafe parameters are observed. Ultimately, this device has the potential to reduce medication errors in hospital settings.

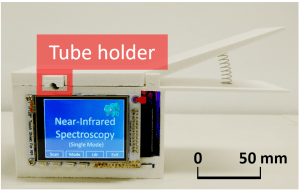

Our system uses Near Infrared Spectroscopy (NIRS) to perform sample scanning. Previous research has used NIRS to detect and classify solid objects (like pills), but liquids are notoriously more challenging to detect and classify due to their physical properties. In our work, we overcome the associated challenges we built a mobile standalone device which includes a NIRS scanner and a 3D printed clamp. The clamp can be attached to an arbitrary tube (like a straw or IV line) to sense the liquid.

Our system enables the use of NIRS for identifying liquids in everyday settings by non-professional end-users. This allows the development of end-user applications that take advantage of liquid-sensing capabilities, such as identifying medicine in an IV line. However, there is potential for this work outside hospital settings, for example by estimating the sugar level in soft drinks that one consumes, or estimating the alchohol level of drinks.

NIRS is a rapid and accessible method for general-purpose matter analysis tasks. It is based on the fact that dissimilar chemical bounds absorb different wavelengths of near-infrared (NIR) lights. Thus, the NIRS spectra collected by our scanning device can be considered as a chemical “fingerprint” of the material. Using machine learning we are able to identify the liquids, or their concentration, by using our reference database.